Understanding Clamp-On Pallet Forks for Tractor Buckets

Boosting farm efficiency often hinges on the right tools. Clamp-on pallet forks, designed to attach to your tractor's bucket, offer a versatile solution for moving materials quickly and efficiently. These attachments transform your tractor into a mobile material handler, ideal for moving feed, supplies, harvested crops, and more. However, it's crucial to understand their strengths and limitations before investing. While offering significant potential benefits, the current market data is limited, creating a need for careful consideration and prioritizing safe operating practices. For more powerful tractor attachments, check out this tractor attachment guide.

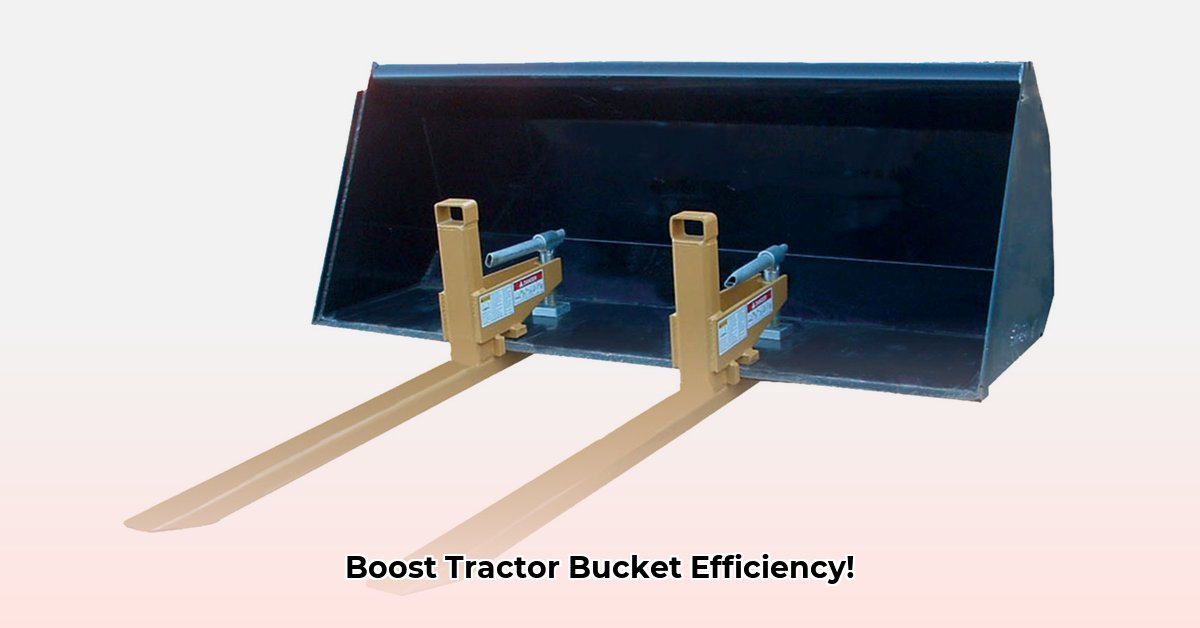

How Clamp-On Pallet Forks Work: A Detailed Look

Clamp-on pallet forks function as powerful "tongs" attaching to your tractor bucket. Two sturdy tines (prong-like extensions) grip the pallet's base, allowing the tractor's hydraulics to lift and move the load. Attachment typically involves a clamping or locking mechanism that integrates with your bucket's arms, often secured by pins or bolts. Always consult your tractor and fork manuals for precise installation instructions. Improper attachment can lead to serious equipment damage or injury. [Diagram illustrating the attachment and operation would ideally be placed here].

Key Features and Considerations: Weighing the Options

Choosing the right clamp-on pallet forks depends on several factors. Weight capacity is paramount; never exceed the rated limit. Fork length should match your typical pallet dimensions, while adjustability allows for handling varying pallet widths. The material—usually heavy-duty steel—affects strength and durability. Finally, consider safety features like stabilizer bars which significantly improve stability, particularly on uneven terrain. While specific comparative data is currently limited, these features are crucial for safe and effective operation.

Selecting the Right Pallet Forks: A Practical Guide

Choosing the best clamp-on pallet forks requires careful assessment. Ask yourself these crucial questions:

- Typical Load Weight: What's the heaviest pallet you'll regularly lift? Add a safety margin when choosing weight capacity.

- Pallet Dimensions: Measure your pallets – fork length must accommodate them securely.

- Working Environment: Consider terrain and space constraints to determine appropriate fork length and stability features.

- Tractor Capacity: Ensure the combined weight of the forks and maximum load doesn't exceed your tractor's lifting capacity.

- Budget: Prices vary widely; balance cost with your specific needs.

Thorough consideration of these factors will significantly increase your chances of choosing the right equipment for your operations.

Safety Precautions: Prioritizing Safety

Safety is non-negotiable when using clamp-on pallet forks. Always:

- Inspect: Thoroughly inspect forks and attachments before each use.

- Assess: Accurately assess load weight and stability; unevenly distributed loads increase risk.

- Lift Gradually: Raise loads slowly and smoothly, preventing jerky movements.

- Maneuver Carefully: Operate cautiously, especially during turns or in confined spaces. Maintain a slow, controlled speed.

- Emergency Stops: Be ready to stop immediately if anything seems amiss.

- Communicate: Maintain clear communication if working with others.

- Maintain: Regular inspection and lubrication are vital for longevity and safety.

A momentary lapse in concentration can have severe consequences.

Maintenance and Care: Extending Fork Lifespan

Simple maintenance extends the lifespan of your forks. This includes:

- Post-Use Inspection: Check for damage after each use.

- Lubrication: Lubricate moving parts regularly, according to the manufacturer's instructions.

- Storage: Store forks in a dry, protected place to prevent corrosion.

These steps minimize wear and tear, saving you money in the long run.

Conclusion: Potential and Limitations

Clamp-on pallet forks offer significant potential for increasing farm efficiency. However, the lack of extensive comparative data currently limits the ability to definitively recommend specific products. Further research and testing are needed to provide a more comprehensive understanding of the available options and their performance under diverse operating conditions. Prioritizing safety and careful selection based on your individual needs are key to maximizing the benefits of these versatile attachments.